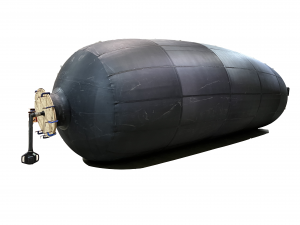

Surge Vessel Bladders

Butyl Products Ltd have been manufacturing Surge Vessel Bladders in the UK since the 1970s, and is regarded as one of the leading manufacturers of these products globally. Our bladders are bespoke and can be produced to most shapes and sizes in accordance with individual customer requirements.

The majority of our Surge Vessel Bladders are produced from a high quality 3 ply 1.50mm Butyl Rubber with all vulcanised joints.

We can also produce surge vessel bladders in EPDM, Polyurethane and Polypropylene if required.

All of our bladders are air tested and supplied with a test report and certificate of conformity, giving our customers peace of mind that the product has been manufactured to the highest standards by skilled technicians.

Our Engineers are on hand to use their extensive experience to provide guidance on ensuring that the Surge Vessel Bladder that we offer is appropriate for your system.

Our class leading manufacturing operation will provide you with an unrivalled manufacturing lead time of 2 weeks from receipt of order – for system breakdowns we can also offer to put on an additional shift to manufacture the bladder tank within 72 hours from receipt of order.

Features available:

Lifting straps – internal to prevent bladders from slumping into the steel chamber during installation.

Reinforcement patches – to prevent abrasion or extrusion through metal

Inlets/Outlets (Flanged Necks)

Handles / Restraint hooks – for holding the bladder in position.

Neck and body reinforcements – usually required for large bladders where the material needs assistance to support its own weight.